Inclined screw conveyor with hopper for conveying materials

Description:

Tubular screw conveyors and feeders have a wide range of applications in powder and granular material handling. Depending on the material being transported, different types of conveyors and feeders can be selected, for example: concrete products (cement, fly ash, filler dust, dust), bituminous products (hot and cold process dust), building ready-mix materials (Dried lime, sand, cement, fillers), glass technology (limestone, soda ash, sand, etc.), foundry (sand, bentonite), etc.

Structure size:

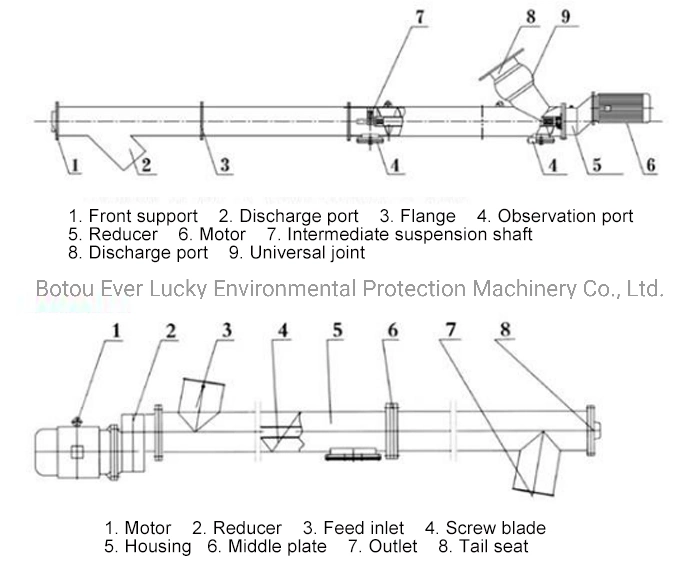

7 kinds of standard pipe outer pipe include welding end flange, feed port, discharge port, observation window below the feed port and middle hanging bearing, spiral blade welded on the center pipe, the end bearing assembly contains self-adjustment Shaft sealing equipment, splined bushings, and lifting eye for each pipe section. Spiral blade types are small in overall size, compact in size, and spare parts are less in number. Maintenance is easy to install.

The tube screw conveyor has the following advantages:

1. The structure is relatively simple and the cost is low.

2. Reliable work, easy maintenance and management.

3. Compact size, small cross-section size, small footprint. It is easy to get in and out of hatches and carriages during unloading operations at the port.

4. Sealed delivery can be achieved, which is conducive to the delivery of materials that are easy to fly, hot and odor, can reduce environmental pollution, and improve the working conditions of port workers.

5. Easy to load and unload. The horizontal screw conveyor can be loaded and unloaded at any point on its conveying line; the vertical screw conveyor can be equipped with a relative screw type picking device and can have excellent reclaiming performance; the screw shaft directly contacting the material pile has automatic retrieving. The capacity can be used as a reclaimer for other types of unloading machinery at ports.

6. The reverse conveying can also enable a conveyor to convey material in two directions at the same time, namely to the center or away from the center.

7. The unit consumes more energy.

8. The materials are easily crushed and worn in the process of transportation, and the spiral blades and troughs are also worn more seriously.

2. Reliable work, easy maintenance and management.

3. Compact size, small cross-section size, small footprint. It is easy to get in and out of hatches and carriages during unloading operations at the port.

4. Sealed delivery can be achieved, which is conducive to the delivery of materials that are easy to fly, hot and odor, can reduce environmental pollution, and improve the working conditions of port workers.

5. Easy to load and unload. The horizontal screw conveyor can be loaded and unloaded at any point on its conveying line; the vertical screw conveyor can be equipped with a relative screw type picking device and can have excellent reclaiming performance; the screw shaft directly contacting the material pile has automatic retrieving. The capacity can be used as a reclaimer for other types of unloading machinery at ports.

6. The reverse conveying can also enable a conveyor to convey material in two directions at the same time, namely to the center or away from the center.

7. The unit consumes more energy.

8. The materials are easily crushed and worn in the process of transportation, and the spiral blades and troughs are also worn more seriously.

Model number | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

Screw diameter(mm) | 140 | 163 | 187 | 238 | 290 | 365 | ||

Rotating speed(r/min) | 300 | 300 | 260 | 200 | 175/300 | 175 | ||

Outer diameter(mm) | 168 | 194 | 219 | 273 | 325 | 402 | ||

Max length(m) | 11 | 12 | 13 | 16 | 18 | 18 | ||

Incline degree(α°) | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~55° | 0°~55° | ||

Conveying capacity(t/h) | 17-9 | 30-20 | 50-32 | 70-53 | 82-60/120-85 | 140-110 | ||

Motor | Model | L≤-7 | Y132S-4 | Y132S-4 | Y132M-4 | Y160L-6 | Y180M-4 | Y180M-4 |

Power(kw) | 5.5 | 5.5 | 7.5 | 11 | 18.5 | 18.5 | ||

Model | L>7 | Y132S-4 | Y132M-4 | Y160M-4 | Y180L-6 | Y180L-4 | Y180L-4 | |

Power(kw) | 5.5 | 7.5 | 11 | 15 | 22 | 22 | ||

.